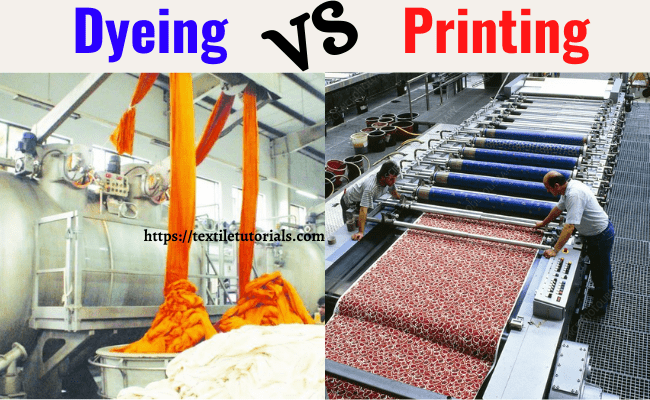

Common Difference Between Dyeing and Printing

What is Dyeing in Textile?

Dyeing is one of the very important departments of the textile sector. All kinds of yarn, fabric are dyed by applying dyeing application, where liquor ratio is higher than printing. It should be noted here that, color penetrates through the fabric by applying dyeing application. It is also a cheap process than printing.

What is Printing in Textile?

Printing is normally done on a fabric surface where the liquor ratio is lower than dyeing application. In the case of the printing method, the curing process is must needed. Another thing is that printing is a costly process than dyeing.

Difference Between Dyeing and Printing in Textile:

| SL No. | Dyeing | Printing |

| 01 | In the case of dyeing, dyes are applied to the whole fabric with equal quantity. | In the case of printing, dyes are applied in the definite parts of fabric for producing design. |

| 02 | During batch application, more time is required. | Less time is required than dyeing application. |

| 03 | Here, the liquor ratio is higher. | Less liquor ratio here than dyeing application. |

| 04 | Precise temperature is needed here. | Precise temperature is not needed in the case of printing applications. |

| 05 | A curing or steaming process is not needed here. | The curing or steaming process is needed for printing applications. |

| 06 | Thickener is not used here. | Thickener is widely used here. |

| 07 | Not expensive. | Expensive. |

| 08 | Here, color penetrates throughout the fabric. | Here, color is applied only on the fabric surface. |

| 09 | The fabric becomes soft after dyeing application. | Printed fabrics will be harsh and hard after applying the printing application. |

| 10 | The quantity of water is required more here. | Less amount of water is needed here. |

| 11 | Only one dye is used in the case of dyeing application. | Here, one or more dye is used during the application of printing. |

| 12 | Half bleaching is enough for fabric preparation before applying the dyeing application. | Full bleaching with optical whitener is needed in case of printing application. |

| 13 | Dye solution concentration is less in the dye bath. | Printing paste concentration is higher in printing. |

| 14 | Fibers, yarn, and fabrics are dyed by applying the dyeing application. | Normally, printing is done on a fabric surface |

| 15 | Precise design is not needed here. | Here, precise design is a must needed. |

Dyeing and printing are two distinct processes used to add color to textiles, but they differ in their methods, applications, and effects on the fabric. Here’s a breakdown of the differences:

1. Process:

Dyeing:

- Method: Dyeing involves immersing the entire fabric, yarn, or fiber into a dye solution to uniformly apply color. The dye penetrates the fibers, coloring the material evenly.

- Application: Dyeing can be done at various stages of textile production, such as fiber, yarn, or fabric dyeing.

Printing:

- Method: Printing is a localized application of color on the fabric surface using specific patterns or designs. The dye or pigment is applied only to certain areas, creating designs on the fabric.

- Application: Printing is generally done on the finished fabric to produce patterns like stripes, florals, or logos.

2. Coverage:

Dyeing:

- Result: The entire fabric or material is colored uniformly. There is no specific pattern, just a solid or blended color.

Printing:

- Result: Only certain areas of the fabric are colored, resulting in patterns or designs. The background fabric remains untouched by the print color.

3. Depth of Color:

Dyeing:

- Penetration: The color penetrates deeply into the fibers, providing a more durable and consistent coloration.

Printing:

- Surface-Level: The color is mostly on the surface, which can sometimes lead to less durability, especially with pigments that might fade or wear off over time.

4. Complexity:

Dyeing:

- Simplicity: Dyeing is generally simpler in terms of design, as it involves coloring the whole material in one or multiple shades.

Printing:

- Complexity: Printing allows for more complex and intricate designs, with the possibility of using multiple colors and creating detailed patterns.

5. Equipment:

Dyeing:

- Equipment: Dyeing processes typically use dyeing vats, jiggers, or continuous dyeing machines, depending on the stage of production and material.

Printing:

- Equipment: Printing requires specialized equipment like screen printers, digital printers, or roller printers, especially for mass production of patterns.

6. Purpose:

Dyeing:

- Purpose: Primarily used to achieve uniform color throughout the material. Ideal for producing solid-colored fabrics.

Printing:

- Purpose: Focuses on creating decorative designs and patterns on the fabric, making it more suitable for fashion, home textiles, and branding.

7. Types:

Dyeing:

- Types: Includes methods like vat dyeing, piece dyeing, yarn dyeing, and solution dyeing.

Printing:

- Types: Includes techniques like screen printing, digital printing, block printing, and transfer printing.

8. Sustainability and Environmental Impact:

Dyeing:

- Impact: Can be water-intensive and may involve chemicals that require proper disposal. However, advancements in sustainable dyeing practices are reducing the environmental impact.

Printing:

- Impact: While printing uses less water, the inks and pigments can still have environmental consequences if not managed properly. Digital printing is a more eco-friendly option compared to traditional methods.

Difference between wet dying and reactive dying